| Argentina | Anasagasti Crespi Hispano-Argentina IAME IKA |

| Australia | Elfin Sports Cars FPV Holden HSV Tickford |

| Belgium | Auto-Mixte Gillet Nagant Pieper |

| Brazil | Agrale Lobini TAC Motors Troller |

| Defunct | Puma Gurgel |

| Canada | Bricklin Studebaker Derby |

| Czech Republic | Avia Kaipan Praga Skoda Auto Tatra |

| France | Aixam Alpine Citroen Delahaye Facel Hommell Ligier Microcar MDI Pescarolo Sport Peugeot Renault Bugatti |

| Germany | Audi AWZ Barkas Bitter BMW Borgward Bugatti Büssing DKW Glas Goliath Hansa Heinkel Horch Lloyd Maybach MAN Mansory Mercedes-Benz Multicar NAG Neoplan Opel Porsche Robur Simson Trabant Volkswagen Wanderer RUF Wiesmann |

| India | Bajaj Hero MotoCorp Maruti Motors Mahindra & Mahindra Limited TAFE Tata Motors TVS Premier Automobiles Limited Ashok Leyland Chinkara Motors DC Design Force Motors Hindustan Motors Eicher ICML GKD |

| Iran | Bahman Group IKCO (Iran Khodro) Kerman Motors Kish Khodro MVM Pars Khodro SAIPA HARISARU |

| Italy | Alfa Romeo DR Motor Ferrari Fiat Intermeccanica Lamborghini Lancia Maserati Pagani Siata Vignale De Tomaso Autobianchi Cizeta |

| Japan | Acura Daihatsu Datsun Hino Honda Infiniti Isuzu Lexus Mazda Mitsubishi Motors Mitsuoka Nissan Scion Subaru Suzuki Toyota Yamaha Dome Motors |

| Malaysia | Bufori Inokom Naza Perodua Proton TD2000 |

| Mexico | Mastretta DINA Tranvias-Cimex Italika |

| Manaco | Venturi |

| Netherlands | DAF Huet Brothers Donkervoort Spyker |

| Pakistan | Daewoo Hinopak Motors Dewan Farooque Motors Ghandhara Industries |

| Poland | Syrena Fabryka Samochodów Osobowych Warszawa (car) ZSD Nysa FSC Żuk |

| Romania | Automobile Dacia ARO Oltcit Tractorul Braşov |

| Russia | Avtoframos GAZ (Volga) Lada Marussia Motors Moskvitch Russo-Balt UAZ Yo-Mobile Zil |

| Serbia | FAP - Fabrika Automobila Priboj Ikarbus Neobus Fiat Automobili Srbija Zastava special cars Industry of Machinery and Tractors |

| Sri Lanka | Micro (cars) |

| South Africa | BMW South Africa Ford Motor Company of Southern Africa General Motors Southern Africa Mercedes-Benz South Africa Nissan South Africa Renault South Africa Toyota South Africa Volkswagen Group South Africa |

| South Korea | GM Daewoo(Chevrolet Korea) Hyundai Motor Company Kia Motors Renault Samsung Motors SsangYong Motor Company Proto Motors |

| Spain | Irizar SEAT Tauro Sport Auto Tramontana |

| Sweden | Koenigsegg Jösse Car Saab Scania Volvo |

| Switzerland | Enzmann Stealth Sbarro (automobile) |

| Thailand | Thai Rung Union Car |

| Turkey | Tofaş-Fiat Anadol Otosan Karsan Oyak-Renault Otokar Temsa BMC (Turkey) Toyota Hyundai Assan Isuzu Anadolu Turk Traktor Hattat Mercedes-Benz Turkey Honda Turkey |

| United Kingdoms | AC Allard Alvis Armstrong Siddeley Ascari Aston Martin Austin Austin-Healey Bentley Bristol British Leyland Caterham Daimler Elva Ford Ginetta Gordon Keeble Hillman Humber Jaguar Cars Jensen Jowett Lanchester Land Rover Gengatharan automobiles limited Lister Lotus Marcos McLaren Automotive MG MG Cars Mini Mini Cooper Morgan Morris Noble Riley Rolls Royce Rover Singer Standard Sunbeam Triumph Trojan TVR Vauxhall Wolseley |

| United States | Buick Cadillac Chevrolet Coda Chrysler Dodge Dodge Ram Fisker Ford Fiat Global Electric Motorcars GMC Hyundai International Harvester Jeep Kia Lincoln Navistar International Tesla Callaway Saleen Panoz Mosler E-Z-GO Nissan Toyota Volvo |

| Defunt US | American Motors Apollo Auburn Bates Motor company Cord Davis Motor Car DeLorean Motor Company Duesenberg Eagle Edsel Essex Geo Graham-Paige Hummer Hupmobile Kaiser Motors Kissel Motor Car Company Laforza Lasalle Locomobile Marmon Mercury Nash Motors Oldsmobile Packard Pierce-Arrow Plymouth Pontiac Regal REO Saturn Sterling Studebaker Tucker Thomas B. Jeffery Company Willys Sound |

| Uzbekistan | GM Uzbekistan JV MAN Auto – Uzbekistan SamAvto |

Showing posts with label Automobile Engg. Show all posts

Showing posts with label Automobile Engg. Show all posts

Sunday, 14 July 2013

Vehicles by Country Wise

Saturday, 6 July 2013

How Air Bags Works

Imagine you're in your car driving home. The weather isn't particularly bad, the road conditions are fine, and you're singing along with the radio. Then out of nowhere, a car makes an illegal turn, winds up in front of you, and you don't have time to stop. You hear the screech of metal as your car collides with the other, and brace yourself to go flying through the windshield. Instead, you are pushed backward into your seat, held there for a split second, and then the pressure subsides. Your seatbelt was the first line of defense but you are upright in the driver's seat because your car is equipped with a vehicle airbag.

Manufacturers have many different names for their systems:

*Supplementary Restraint System (SRS) *Air Cushion Restraint System (ACRS)

*Supplemental Inflatable Restraint (SIR)

But, they all have the same purpose and operation.

Airbags are supplemental restraints. Supplemental means they help another system, or they are secondary to another system. In this case it is the seat belt. Though later airbags are required to be able to, airbags are not meant to be used without a seat belt; in fact they can be very dangerous or even deadly without a seat belt.Contrary to what a lot of people think air bags are not made to stop you from lunging forward during a crash. In a crash, let’s say 30 mph, the car is moving 30 mph and your body is moving 30 mph along with it, if the car hits a wall and stops, not being part of the car your body is still moving at 30 mph, causing you to lunge forward.

This is the job of the seat belt, to hold you in place.

Have you ever wondered how race car drivers have such horrible crashes and never get hurt?

Let’s look at a race car, with a five point harness the driver is a stationary part of the seat. He can not move forward or backward, there is no slack in the harness, he is actually a part of the car. Then look at the 200 mph crashes they walk away from without a scratch. Why? Because his body stopped at the same time as the car did. Now look at a passenger vehicle: Who wants to be restrained that tight in a car on the city streets, or on a long trip? Our seat belts have some slack in them; therefore not being a stationary part of the vehicle, we are going to lunge forward some what in a crash.

This is where the air bag, or supplement, comes in.

The air bag deploys at 200-300 mph, depending on the manufacture. From the time of impact to the time of full airbag deployment is from 21 to 27 milli-seconds. This means it is already fully deployed before yourbody ever lunges forward.

The idea is for the air bag to be deployed, so fast that it is fully inflated, before your body is thrown forward. Then as you fall into the bag, it should have already started to deflate. The bag then lowers you down at a slower speed and cushions you.

The design is conceptually simple; a central "Airbag control unit"(ACU) (a specific type of ECU) monitors a number of related sensors within the vehicle, including accelerometers, impact sensors, side (door) pressure sensors,wheel speed sensors, gyroscopes, brake pressure sensors, and seat occupancy sensors. The bag itself and its inflation mechanism is concealed within the steering wheel boss (for the driver), or the dashboard (for the front passenger), behind plastic flaps or doors which are designed to "tear open" under the force of the bag inflating. Once the requisite 'threshold' has been reached or exceeded, the airbag control unit will trigger the ignition of a gas generator propellant to rapidly inflate a fabric bag. As the vehicle occupant collides with and squeezes the bag, the gas escapes in a controlled manner through small vent holes. The airbag's volume and the size of the vents in the bag are tailored to each vehicle type, to spread out the deceleration of (and thus force experienced by) the occupant over time and over the occupant's body, compared to a seat belt alone.

The signals from the various sensors are fed into the Airbag control unit, which determines from them the angle of impact, the severity, or force of the crash, along with other variables. Depending on the result of these calculations, the ACU may also deploy various additional restraint devices, such as seat belt pre-tensioners, and/or airbags (including frontal bags for driver and front passenger, along with seat-mounted side bags, and "curtain" airbags which cover the side glass). Each restraint device is typically activated with one or more pyrotechnic devices, commonly called an initiator or electric match. The electric match, which consists of an electrical conductor wrapped in a combustible material, activates with a current pulse between 1 to 3 amperes in less than 2 milliseconds. When the conductor becomes hot enough, it ignites the combustible material, which initiates the gas generator. In a seat belt pre-tensioner, this hot gas is used to drive a piston that pulls the slack out of the seat belt. In an airbag, the initiator is used to ignite solid propellant inside the airbag inflator. The burning propellant generates inert gas which rapidly inflates the airbag in approximately 20 to 30 milliseconds. An airbag must inflate quickly in order to be fully inflated by the time the forward-traveling occupant reaches its outer surface. Typically, the decision to deploy an airbag in a frontal crash is made within 15 to 30 milliseconds after the onset of the crash, and both the driver and passenger airbags are fully inflated within approximately 60-80 milliseconds after the first moment of vehicle contact. If an airbag deploys too late or too slowly, the risk of occupant injury from contact with the inflating airbag may increase. Since more distance typically exists between the passenger and the instrument panel, the passenger airbag is larger and requires more gas to fill it.

Front airbags normally do not protect the occupants during side, rear, or rollover accidents.Since airbags deploy only once and deflate quickly after the initial impact, they will not be beneficial during a subsequent collision. Safety belts help reduce the risk of injury in many types of crashes. They help to properly position occupants to maximize the airbag's benefits and they help restrain occupants during the initial and any following collisions.

In vehicles equipped with a rollover sensing system, accelerometers and gyroscopes are used to sense the onset of a rollover event. If a rollover event is determined to be imminent, side-curtain airbags are deployed to help protect the occupant from contact with the side of the vehicle interior, and also to help prevent occupant ejection as the vehicle rolls over.

Chemistry Behind Air Bags:

Inside the airbag is a gas generator containing a mixture of NaN3, KNO3, and SiO2. When the car undergoes a head-on collision, a series of three chemical reactions inside the gas generator produce gas (N2) to fill the airbag and convert NaN3, which is highly toxic (The maximum concentration of NaN3 allowed in the workplace is 0.2 mg/m3 air.), to harmless glass (Table 1). Sodium azide (NaN3) can decompose at 300oC to produce sodium metal (Na) and nitrogen gas (N2). The signal from the deceleration sensor ignites the gas-generator mixture by an electrical impulse, creating the high-temperature condition necessary for NaN3 to decompose. The nitrogen gas that is generated then fills the airbag. The purpose of the KNO3 and SiO2 is to remove the sodium metal (which is highly reactive and potentially explosive, as you recall from the Periodic Properties Experiment) by converting it to a harmless material. First, the sodium reacts with potassium nitrate (KNO3) to produce potassium oxide (K2O), sodium oxide (Na2O), and additional N2 gas. The N2 generated in this second reaction also fills the airbag, and the metal oxides react with silicon dioxide (SiO2) in a final reaction to produce silicate glass, which is harmless and stable. (First-period metal oxides, such as Na2O and K2O, are highly reactive, so it would be unsafe to allow them to be the end product of the airbag detonation).

Manufacturers have many different names for their systems:

*Supplementary Restraint System (SRS) *Air Cushion Restraint System (ACRS)

*Supplemental Inflatable Restraint (SIR)

But, they all have the same purpose and operation.

Airbags are supplemental restraints. Supplemental means they help another system, or they are secondary to another system. In this case it is the seat belt. Though later airbags are required to be able to, airbags are not meant to be used without a seat belt; in fact they can be very dangerous or even deadly without a seat belt.Contrary to what a lot of people think air bags are not made to stop you from lunging forward during a crash. In a crash, let’s say 30 mph, the car is moving 30 mph and your body is moving 30 mph along with it, if the car hits a wall and stops, not being part of the car your body is still moving at 30 mph, causing you to lunge forward.

This is the job of the seat belt, to hold you in place.

Have you ever wondered how race car drivers have such horrible crashes and never get hurt?

Let’s look at a race car, with a five point harness the driver is a stationary part of the seat. He can not move forward or backward, there is no slack in the harness, he is actually a part of the car. Then look at the 200 mph crashes they walk away from without a scratch. Why? Because his body stopped at the same time as the car did. Now look at a passenger vehicle: Who wants to be restrained that tight in a car on the city streets, or on a long trip? Our seat belts have some slack in them; therefore not being a stationary part of the vehicle, we are going to lunge forward some what in a crash.

This is where the air bag, or supplement, comes in.

The air bag deploys at 200-300 mph, depending on the manufacture. From the time of impact to the time of full airbag deployment is from 21 to 27 milli-seconds. This means it is already fully deployed before yourbody ever lunges forward.

The idea is for the air bag to be deployed, so fast that it is fully inflated, before your body is thrown forward. Then as you fall into the bag, it should have already started to deflate. The bag then lowers you down at a slower speed and cushions you.

The design is conceptually simple; a central "Airbag control unit"(ACU) (a specific type of ECU) monitors a number of related sensors within the vehicle, including accelerometers, impact sensors, side (door) pressure sensors,wheel speed sensors, gyroscopes, brake pressure sensors, and seat occupancy sensors. The bag itself and its inflation mechanism is concealed within the steering wheel boss (for the driver), or the dashboard (for the front passenger), behind plastic flaps or doors which are designed to "tear open" under the force of the bag inflating. Once the requisite 'threshold' has been reached or exceeded, the airbag control unit will trigger the ignition of a gas generator propellant to rapidly inflate a fabric bag. As the vehicle occupant collides with and squeezes the bag, the gas escapes in a controlled manner through small vent holes. The airbag's volume and the size of the vents in the bag are tailored to each vehicle type, to spread out the deceleration of (and thus force experienced by) the occupant over time and over the occupant's body, compared to a seat belt alone.

The signals from the various sensors are fed into the Airbag control unit, which determines from them the angle of impact, the severity, or force of the crash, along with other variables. Depending on the result of these calculations, the ACU may also deploy various additional restraint devices, such as seat belt pre-tensioners, and/or airbags (including frontal bags for driver and front passenger, along with seat-mounted side bags, and "curtain" airbags which cover the side glass). Each restraint device is typically activated with one or more pyrotechnic devices, commonly called an initiator or electric match. The electric match, which consists of an electrical conductor wrapped in a combustible material, activates with a current pulse between 1 to 3 amperes in less than 2 milliseconds. When the conductor becomes hot enough, it ignites the combustible material, which initiates the gas generator. In a seat belt pre-tensioner, this hot gas is used to drive a piston that pulls the slack out of the seat belt. In an airbag, the initiator is used to ignite solid propellant inside the airbag inflator. The burning propellant generates inert gas which rapidly inflates the airbag in approximately 20 to 30 milliseconds. An airbag must inflate quickly in order to be fully inflated by the time the forward-traveling occupant reaches its outer surface. Typically, the decision to deploy an airbag in a frontal crash is made within 15 to 30 milliseconds after the onset of the crash, and both the driver and passenger airbags are fully inflated within approximately 60-80 milliseconds after the first moment of vehicle contact. If an airbag deploys too late or too slowly, the risk of occupant injury from contact with the inflating airbag may increase. Since more distance typically exists between the passenger and the instrument panel, the passenger airbag is larger and requires more gas to fill it.

Front airbags normally do not protect the occupants during side, rear, or rollover accidents.Since airbags deploy only once and deflate quickly after the initial impact, they will not be beneficial during a subsequent collision. Safety belts help reduce the risk of injury in many types of crashes. They help to properly position occupants to maximize the airbag's benefits and they help restrain occupants during the initial and any following collisions.

In vehicles equipped with a rollover sensing system, accelerometers and gyroscopes are used to sense the onset of a rollover event. If a rollover event is determined to be imminent, side-curtain airbags are deployed to help protect the occupant from contact with the side of the vehicle interior, and also to help prevent occupant ejection as the vehicle rolls over.

Chemistry Behind Air Bags:

Inside the airbag is a gas generator containing a mixture of NaN3, KNO3, and SiO2. When the car undergoes a head-on collision, a series of three chemical reactions inside the gas generator produce gas (N2) to fill the airbag and convert NaN3, which is highly toxic (The maximum concentration of NaN3 allowed in the workplace is 0.2 mg/m3 air.), to harmless glass (Table 1). Sodium azide (NaN3) can decompose at 300oC to produce sodium metal (Na) and nitrogen gas (N2). The signal from the deceleration sensor ignites the gas-generator mixture by an electrical impulse, creating the high-temperature condition necessary for NaN3 to decompose. The nitrogen gas that is generated then fills the airbag. The purpose of the KNO3 and SiO2 is to remove the sodium metal (which is highly reactive and potentially explosive, as you recall from the Periodic Properties Experiment) by converting it to a harmless material. First, the sodium reacts with potassium nitrate (KNO3) to produce potassium oxide (K2O), sodium oxide (Na2O), and additional N2 gas. The N2 generated in this second reaction also fills the airbag, and the metal oxides react with silicon dioxide (SiO2) in a final reaction to produce silicate glass, which is harmless and stable. (First-period metal oxides, such as Na2O and K2O, are highly reactive, so it would be unsafe to allow them to be the end product of the airbag detonation).

Tuesday, 18 June 2013

Anti Break Locking System

When the driver brakes hard on a slippery road surface, the anti-lock braking system prevents the wheels from locking, so that the vehicle can still be steered.

When the wheels lock up, they are no longer able to transmit cornering forces, meaning that the driver loses control of the vehicle. To prevent this from happening, the ABS control unit uses wheel speed sensors to monitor the rotational speed of each wheel. If it detects that a wheel is about to lock, a solenoid valve in the anti-lock braking system's central control element reduces the brake pressure applied at the wheel in question until it starts to rotate freely again. The pressure is subsequently increased to the lock-up threshold again. The vehicle remains stable and can still be steered.

Since most cars on the road today have some form of Antilock Brakes (ABS) I think we should take a look at how they work and clear up some mis-information about them.

As always, what I describe here is how most systems work in general. Since different manufacturers have their own versions of ABS their specifications and part names may differ. If you're having a problem with the ABS on your vehicle you should always refer to the specific service and repair manuals for your vehicle.

The ABS is a four-wheel system that prevents wheel lock-up by automatically modulating the brake pressure during an emergency stop. By preventing the wheels from locking, it enables the driver to maintain steering control and to stop in the shortest possible distance under most conditions. During normal braking, the ABS and non-ABS brake pedal feel will be the same. During ABS operation, a pulsation can be felt in the brake pedal, accompanied by a fall and then rise in brake pedal height and a clicking sound.

Vehicles with ABS are equipped with a pedal-actuated, dual-brake system. The basic hydraulic braking system consists of the following:

*ABS hydraulic control valves and electronic control unit

*Brake master cylinder

*Necessary brake tubes and hoses

The anti-lock brake system consists of the following components:

*Hydraulic Control Unit (HCU).

*Anti-lock brake control module.

*Front anti-lock brake sensors / rear anti-lock brake sensors.

Anti-lock Brake Systems (ABS) operate as follows:

1.When the brakes are applied, fluid is forced from the brake master cylinder outlet ports to the HCU inlet ports. This pressure is transmitted through four normally open solenoid valves contained inside the HCU, then through the outlet ports of the HCU to each wheel.

2.The primary (rear) circuit of the brake master cylinder feeds the front brakes.

3.The secondary (front) circuit of the brake master cylinder feeds the rear brakes.

4.If the anti-lock brake control module senses a wheel is about to lock, based on anti-lock brake sensor data, it closes the normally open solenoid valve for that circuit. This prevents any more fluid from entering that circuit.

5.The anti-lock brake control module then looks at the anti-lock brake sensor signal from the affected wheel again.

6.If that wheel is still decelerating, it opens the solenoid valve for that circuit.

7.Once the affected wheel comes back up to speed, the anti-lock brake control module returns the solenoid valves to their normal condition allowing fluid flow to the affected brake.

8.The anti-lock brake control module monitors the electromechanical components of the system.

9.Malfunction of the anti-lock brake system will cause the anti-lock brake control module to shut off or inhibit the system. However, normal power-assisted braking remains.

10.Loss of hydraulic fluid in the brake master cylinder will disable the anti-lock system. [li[The 4-wheel anti- lock brake system is self-monitoring. When the ignition switch is turned to the RUN position, the anti- lock brake control module will perform a preliminary self-check on the anti-lock electrical system indicated by a three second illumination of the yellow ABS wanting indicator.

11.During vehicle operation, including normal and anti-lock braking, the anti-lock brake control module monitors all electrical anti-lock functions and some hydraulic operations.

12.Each time the vehicle is driven, as soon as vehicle speed reaches approximately 20 km/h (12 mph), the

anti-lock brake control module turns on the pump motor for approximately one-half second. At this time, a mechanical noise may be heard. This is a normal function of the self-check by the anti-lock brake control module.

13.When the vehicle speed goes below 20 km/h (12 mph), the ABS turns off.

14.Most malfunctions of the anti-lock brake system and traction control system, if equipped, will cause the

yellow ABS warning indicator to be illuminated.

Most light trucks and SUVs use a form of ABS known as Rear Wheel ABS. The Rear Wheel Anti Lock (RWAL) system reduces the occurrence of rear wheel lockup during severe braking by regulating rear hydraulic line pressure. The system monitors the speed of the rear wheels during braking. The Electronic Brake Control Module (EBCM) processes these values to produce command controls to prevent the rear wheels from locking.

This system uses three basic components to control hydraulic pressure to the rear brakes. These components are:

*Electronic Brake Control Module

*Anti-Lock Pressure Valve

*Vehicle Speed Sensor

ELECTRONIC BRAKE CONTROL MODULE:

The EBCM mounted on a bracket next to the master cylinder, contains a microprocessor and software for system operation.

ANTI-LOCK PRESSURE VALVE:

The Anti-Lock Pressure Valve (APV) is mounted to the combination valve under the master cylinder, has an isolation valve to maintain or increase hydraulic pressure and a dump valve to reduce hydraulic pressure.

VEHICLE SPEED SENSOR:

The Vehicle Speed Sensor (VSS) located on the left rear of the transmission on two-wheel drive trucks and on the transfer case of four-wheel drive vehicles, produces an AC voltage signal that varies in frequency according to the output shaft speed. On some vehicles the VSS is located in the rear differential.

BASE BRAKING MODE:

During normal braking, the EBCM receives a signal from the stop lamp switch and begins to monitor the vehicle speed line. The isolation valve is open and the dump valve is seated. This allows fluid under pressure to pass through the APV and travel to the rear brake channel. The reset switch does not move because hydraulic pressure is equal on both sides.

ANTILOCK BRAKING MODE:

During a brake application the EBCM compares vehicle speed to the program built into it. When it senses a rear wheel lock-up condition, it operates the anti lock pressure valve to keep the rear wheels from locking up. To do this the EBCM uses a three-step cycle:

*Pressure Maintain

*Pressure Decrease

*Pressure Increase

PRESSURE MAINTAIN:

During pressure maintain the EBCM energizes the isolation solenoid to stop the flow of fluid from the master cylinder to the rear brakes. The reset switch moves when the difference between the master cylinder line pressure and the rear brake channel pressure becomes great enough. If this happens, it grounds the EBCM logic circuit.

PRESSURE DECREASE:

During pressure decrease the EBCM keeps the isolation solenoid energized and energizes the dump solenoid. The dump valve moves off its seat and fluid under pressure moves into the accumulator. This action reduces rear pipe pressure preventing rear lock-up. The reset switch grounds to tell the EBCM that pressure decrease has taken place.

PRESSURE INCREASE:

During pressure increase the EBCM de-energizes the dump and isolation solenoids. The dump valve reseats and holds the stored fluid in the accumulator. The isolation valve 9pens and allows the fluid from the master cylinder to flow past it and increase pressure to the rear brakes. The reset switch moves back to its original position by spring force. This action signals the EBCM that pressure decrease has ended and driver applied pressure resumes.

SYSTEM SELF-TEST:

When the ignition switch is turned "ON," the EBCM performs a system self-test. It checks its internal and external circuit and performs a function test by cycling the isolation and dump valves. The EBCM then begins its normal operation if no malfunctions are detected.

Brake pedal pulsation and occasional rear tire "chirping" are normal during RWAL operation. The road surface and severity of the braking maneuver determine how much these will occur. Since these systems only control the rear wheels, it is still possible to lock the front wheels during certain severe braking conditions.

SPARE TIRE:

Using the spare tire supplied with the vehicle will not affect the performance of the RWAL or system.

REPLACEMENT TIRES:

Tire size can affect the performance of the RWAL system. Replacement tires must be the same size, load range, and construction on all four wheels.

Contrary to popular belief ABS brakes will not stop your car faster. The idea behind ABS brakes is that you maintain control of your vehicle by avoiding wheel lock up. When your wheels lock up you have no steering control and turning the steering wheel to avoid a collision will do you no good. When the wheels stop turning, it's done and over.

When driving on slippery roads you need to allow for increased braking distance since the wheels will lock up much easier and the ABS will cycle much faster. Speed is a factor also, if you're going too fast even the control ABS gives you will not be enough to overcome plain inertia. You may turn the wheel to the left or right, but inertia will keep you going forward.

If there is an ABS failure, the system will revert to normal brake operation so you will not be without brakes. Normally the ABS warning light will turn on and let you know there is a fault. When that light is on it is safe to assume the ABS has switched to normal brake operation and you should drive accordingly.

I hope that this has helped you understand how ABS systems work. It is a technology that has been in use for many years before it was adapted for automotive use. Aircraft have been using some form of ABS since WW II and it is a tried and true system that can be a great help in avoiding accidents if it is used as it was meant to be used.

Advantages of Anti-Lock Brakes:

The main benefits of an anti-lock brake system (ABS) include:

*Stopping on ice:

As mentioned above, an ABS prevents lock-ups and skidding, even in slippery conditions. Anti-lock brakes have been proven to save lives in some situations by helping drivers keep control of a vehicle.

*Lower insurance costs:

Because it is a thoroughly tested safety device with a track record of effectiveness,insurers often give customers specific discounts for having an ABS system on their vehicle.

*Higher resale value:

As a feature on a car or truck, an ABS raises the market value of the vehicle.Nowadays, where ABS technology has become standard on many vehicles, not having it could result in a lower price for resale.

*Traction control:

An ABS shares some of the infrastructure of a traction control system, where new technology helps ensure that each wheel has traction on the road. That makes it easy for manufacturers to install both of these features at the factory.

Disadvantages of Anti-Lock Brakes:

Despite the fact that anti-lock brakes are proven to be a safety feature in most situations, and insurers consider them to significantly lower risk for a vehicle, not all drivers are sold on this option for a car or truck. Here are some of the down sides that drivers find in this kind of brake system.

Inconsistent stop times:

Anti-lock brakes are made to provide for surer braking in slippery conditions. However, some drivers report that they find stopping distances for regular conditions are lengthened by their ABS, either because there may be errors in the system, or because the clunking or noise of the ABS may contribute to the driver not braking at the same rate.

Expense:

An ABS can be expensive to maintain. Expensive sensors on each wheel can cost hundreds of dollars to fix if they get out of calibration or develop other problems. For some, this is a big reason to decline an ABS in a vehicle.

Delicate systems:

It's easy to cause a problem in an ABS by messing around with the brakes. Problems include disorientation of the ABS, where a compensating brake sensor causes the vehicle to shudder, make loud noise or generally brake worse.

Published by Ravindra.K(Mechanical Engineering)

Published by Ravindra.K(Mechanical Engineering)Sunday, 17 March 2013

Carburetor

Introduction:

carburetor, also spelled carburettor , device for supplying a spark-ignition engine with a mixture of fuel and air. Components of carburetors usually include a storage chamber for liquid fuel, a choke, an idling (or slow-running) jet, a main jet, a venturi-shaped air-flow restriction, and an accelerator pump. The quantity of fuel in the storage chamber is controlled by a valve actuated by a float. The choke, a butterfly valve, reduces the intake of air and allows a fuel-rich charge to be drawn into the cylinders when a cold engine is started. As the engine warms up, the choke is gradually opened either by hand or automatically by heat- and engine-speed-responsive controllers. The fuel flows out of the idling jet into the intake air as a result of reduced pressure near the partially closed throttle valve. The main fuel jet comes into action when the throttle valve is further open. Then the venturi-shaped air-flow restriction creates a reduced pressure for drawing fuel from the main jet into the air stream at a rate related to the air flow so that a nearly constant fuel-air ratio is obtained. The accelerator pump injects fuel into the inlet air when the throttle is opened suddenly.

In the 1970s, new legislation and consumer preferences led automobile manufacturers to improve fuel efficiency and lower pollutant emissions. To accomplish these objectives, engineers developed fuel injection management systems based on new computer technologies. Soon, fuel injection systems replaced carbureted fuel systems in virtually all gasoline engines except for two-cycle and small four-cycle gasoline engines, such as those used in lawn mowers.

If you have read the page entitled How Car Engines Work, you know that the idea behind an engine is to burn gasoline to create pressure, and then to turn the pressure into motion. A remarkably tiny amount of gasoline is needed during each combustion cycle. Something on the order of 10 milligrams of gasoline per combustion stroke is all it takes!

The goal of a carburetor is to mix just the right amount of gasoline with air so that the engine runs properly. If there is not enough fuel mixed with the air, the engine "runs lean" and either will not run or potentially damages the engine. If there is too much fuel mixed with the air, the engine "runs rich" and either will not run (it floods), runs very smoky, runs poorly (bogs down, stalls easily), or at the very least wastes fuel. The carb is in charge of getting the mixture just right.

On new cars, fuel injection is becoming nearly universal because it provides better fuel efficiency and lower emissions. But nearly all older cars, and all small equipment like lawn mowers and chain saws, use carbs because they are simple and inexpensive.

Inside a Carburetor:

The carburetor on a chain saw is a good example because it is so straightforward. The carb on a chain saw is simpler than most carbs because it really has only three situations that it has to cover:

*It has to work when you are trying to start the engine cold.

*It has to work when the engine is idling.

*It has to work when the engine is wide open.

No one operating a chain saw is really interested in any gradations between idle and full throttle, so incremental performance between these two extremes is not very important. In a car the many gradations are important, and this is why a car's carb is a lot more complex.

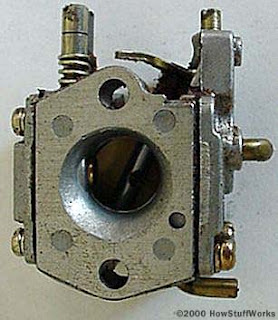

Chainsaw carburetor:

Here are the parts of a carb:

A carburetor is essentially a tube.

There is an adjustable plate across the tube called the throttle plate that controls how much air can flow through the tube. You can see this circular brass plate in photo 2.

At some point in the tube there is a narrowing, called the venturi, and in this narrowing a vacuum is created. The venturi is visible in photo 1

In this narrowing there is a hole, called a jet, that lets the vacuum draw in fuel. You can see the jet on the left side of the venturi in photo 1.

On the step, learn about carburetor tuning and find out why it's so important.

Carburetor Tuning:

The carb is operating "normally" at full throttle. In this case the throttle plate is parallel to the length of the tube, allowing maximum air to flow through the carb. The air flow creates a nice vacuum in the venturi and this vacuum draws in a metered amount of fuel through the jet. You can see a pair of screws on the right top of the carb in photo 2. One of these screws (labeled "Hi" on the case of the chain saw) controls how much fuel flows into the venturi at full throttle.

When the engine is idling, the throttle plate is nearly closed (the position of the throttle plate in the photos is the idle position). There is not really enough air flowing through the venturi to create a vacuum. However, on the back side of the throttle plate there is a lot of vacuum (because the throttle plate is restricting the airflow). If a tiny hole is drilled into the side of the carb's tube just behind the throttle plate, fuel can be drawn into the tube by the throttle vacuum. This tiny hole is called the idle jet. The other screw of the pair seen in photo 2 is labeled "Lo" and it controls the amount of fuel that flows through the idle jet.

Both the Hi and Lo screws are simply needle valves. By turning them you allow more or less fuel to flow past the needle. When you adjust them you are directly controlling how much fuel flows through the idle jet and the main jet.

When the engine is cold and you try to start it with the pull cord, the engine is running at an extremely low RPM. It is also cold, so it needs a very rich mixture to start. This is where the choke plate comes in. When activated, the choke plate completely covers the venturi see this video of the choke plate to see it in action). If the throttle is wide open and the venturi is covered, the engine's vacuum draws a lot of fuel through the main jet and the idle jet (since the end of the carb's tube is completely covered, all of the engine's vacuum goes into pulling fuel through the jets). Usually this very rich mixture will allow the engine to fire once or twice, or to run very slowly. If you then open the choke plate the engine will start running normally.

What does a Carburetor Do?

The carburetor has several functions: 1) it combines gasoline and air creating a highly combustible mixture, 2) it regulates the ratio of air and fuel, and 3) it controls the engine's speed.

How a carburetor mixes fuel and air?

When the piston moves down the cylinder on the intake stroke it draws air from the cylinder and intake manifold. A vacuum is created that draws air from the carburetor. The airflow through the carburetor causes fuel to be drawn from the carburetor through the intake manifold past the intake valves and into the cylinder. The amount of fuel mixed into the air to obtain the required air to fuel ratio is controlled by the venturi or choke. When air flows through the venturi its speed increases and the pressure drops. This causes the fuel to be sucked into the air stream from a hole or jet. When the engine is at idle or at rapid acceleration there is not enough air passing through the venturi to draw fuel. To overcome these problems other systems are used.

Delivering gasoline to the carburetor:

Gasoline is delivered to the carburetor by the fuel pump and is stored in the fuel bowl. To keep this level of fuel stored in the bowl constant under all conditions a float system is used. A float operated needle valve and seat at the fuel inlet is used to control the fuel level in the bowl. If the fuel level drops below a certain level the float lowers and opens the valve letting more fuel in. When the float rises it pushes the inlet valve against the seat and shuts off the flow of fuel into the bowl.

Types of carburetors:

There are 3 basic types of carburetors in use today. They are the one barrel, two barrel, and four barrel. Typically, the type of engine and its use will dictate which carburetor is used. In high performance engines multiple carburetors may be used to deliver the amount of fuel required. No matter what type of carburetor your engine uses, National Carburetors is your source for high quality carburetors.

Controlling the speed of the engine:

The throttle controls the speed of the engine by controlling the amount of air fuel allowed in the engine. The throttle is a butterfly valve located after the venturi and is opened by pressing on the gas pedal. The farther the valve is opened the more air/fuel mixture is let into the engine and the faster the engine runs. At low engine speeds when the throttle is only open a little there is not enough air flow to pull in fuel.

Ports

Two ports are used to solve this problem. One port located in the low pressure area and the idle port located below. At low engine speeds both ports draw fuel to keep the engine running. As engine speed increases fuel from the 2 ports decreases until it stops completely.

Handling low speeds:

When the engine is idle there is very little air flowing through the venturi because the throttle valve is closed. The idle port allows the engine to operate under this condition. Fuel is forced through the idle port because of a pressure differential between air in the fuel bowl and vacuum below the throttle valve. Idle fuel mixture is controlled by an adjustable needle valve.

Handling high speeds

carburetor, also spelled carburettor , device for supplying a spark-ignition engine with a mixture of fuel and air. Components of carburetors usually include a storage chamber for liquid fuel, a choke, an idling (or slow-running) jet, a main jet, a venturi-shaped air-flow restriction, and an accelerator pump. The quantity of fuel in the storage chamber is controlled by a valve actuated by a float. The choke, a butterfly valve, reduces the intake of air and allows a fuel-rich charge to be drawn into the cylinders when a cold engine is started. As the engine warms up, the choke is gradually opened either by hand or automatically by heat- and engine-speed-responsive controllers. The fuel flows out of the idling jet into the intake air as a result of reduced pressure near the partially closed throttle valve. The main fuel jet comes into action when the throttle valve is further open. Then the venturi-shaped air-flow restriction creates a reduced pressure for drawing fuel from the main jet into the air stream at a rate related to the air flow so that a nearly constant fuel-air ratio is obtained. The accelerator pump injects fuel into the inlet air when the throttle is opened suddenly.

In the 1970s, new legislation and consumer preferences led automobile manufacturers to improve fuel efficiency and lower pollutant emissions. To accomplish these objectives, engineers developed fuel injection management systems based on new computer technologies. Soon, fuel injection systems replaced carbureted fuel systems in virtually all gasoline engines except for two-cycle and small four-cycle gasoline engines, such as those used in lawn mowers.

If you have read the page entitled How Car Engines Work, you know that the idea behind an engine is to burn gasoline to create pressure, and then to turn the pressure into motion. A remarkably tiny amount of gasoline is needed during each combustion cycle. Something on the order of 10 milligrams of gasoline per combustion stroke is all it takes!

The goal of a carburetor is to mix just the right amount of gasoline with air so that the engine runs properly. If there is not enough fuel mixed with the air, the engine "runs lean" and either will not run or potentially damages the engine. If there is too much fuel mixed with the air, the engine "runs rich" and either will not run (it floods), runs very smoky, runs poorly (bogs down, stalls easily), or at the very least wastes fuel. The carb is in charge of getting the mixture just right.

On new cars, fuel injection is becoming nearly universal because it provides better fuel efficiency and lower emissions. But nearly all older cars, and all small equipment like lawn mowers and chain saws, use carbs because they are simple and inexpensive.

Inside a Carburetor:

|

| 2.Chainsaw Carburetor |

|

| 1.Chainsaw Carburetor |

*It has to work when you are trying to start the engine cold.

*It has to work when the engine is idling.

*It has to work when the engine is wide open.

No one operating a chain saw is really interested in any gradations between idle and full throttle, so incremental performance between these two extremes is not very important. In a car the many gradations are important, and this is why a car's carb is a lot more complex.

Chainsaw carburetor:

Here are the parts of a carb:

A carburetor is essentially a tube.

There is an adjustable plate across the tube called the throttle plate that controls how much air can flow through the tube. You can see this circular brass plate in photo 2.

At some point in the tube there is a narrowing, called the venturi, and in this narrowing a vacuum is created. The venturi is visible in photo 1

In this narrowing there is a hole, called a jet, that lets the vacuum draw in fuel. You can see the jet on the left side of the venturi in photo 1.

On the step, learn about carburetor tuning and find out why it's so important.

Carburetor Tuning:

The carb is operating "normally" at full throttle. In this case the throttle plate is parallel to the length of the tube, allowing maximum air to flow through the carb. The air flow creates a nice vacuum in the venturi and this vacuum draws in a metered amount of fuel through the jet. You can see a pair of screws on the right top of the carb in photo 2. One of these screws (labeled "Hi" on the case of the chain saw) controls how much fuel flows into the venturi at full throttle.

When the engine is idling, the throttle plate is nearly closed (the position of the throttle plate in the photos is the idle position). There is not really enough air flowing through the venturi to create a vacuum. However, on the back side of the throttle plate there is a lot of vacuum (because the throttle plate is restricting the airflow). If a tiny hole is drilled into the side of the carb's tube just behind the throttle plate, fuel can be drawn into the tube by the throttle vacuum. This tiny hole is called the idle jet. The other screw of the pair seen in photo 2 is labeled "Lo" and it controls the amount of fuel that flows through the idle jet.

Both the Hi and Lo screws are simply needle valves. By turning them you allow more or less fuel to flow past the needle. When you adjust them you are directly controlling how much fuel flows through the idle jet and the main jet.

When the engine is cold and you try to start it with the pull cord, the engine is running at an extremely low RPM. It is also cold, so it needs a very rich mixture to start. This is where the choke plate comes in. When activated, the choke plate completely covers the venturi see this video of the choke plate to see it in action). If the throttle is wide open and the venturi is covered, the engine's vacuum draws a lot of fuel through the main jet and the idle jet (since the end of the carb's tube is completely covered, all of the engine's vacuum goes into pulling fuel through the jets). Usually this very rich mixture will allow the engine to fire once or twice, or to run very slowly. If you then open the choke plate the engine will start running normally.

What does a Carburetor Do?

The carburetor has several functions: 1) it combines gasoline and air creating a highly combustible mixture, 2) it regulates the ratio of air and fuel, and 3) it controls the engine's speed.

How a carburetor mixes fuel and air?

When the piston moves down the cylinder on the intake stroke it draws air from the cylinder and intake manifold. A vacuum is created that draws air from the carburetor. The airflow through the carburetor causes fuel to be drawn from the carburetor through the intake manifold past the intake valves and into the cylinder. The amount of fuel mixed into the air to obtain the required air to fuel ratio is controlled by the venturi or choke. When air flows through the venturi its speed increases and the pressure drops. This causes the fuel to be sucked into the air stream from a hole or jet. When the engine is at idle or at rapid acceleration there is not enough air passing through the venturi to draw fuel. To overcome these problems other systems are used.

Delivering gasoline to the carburetor:

Gasoline is delivered to the carburetor by the fuel pump and is stored in the fuel bowl. To keep this level of fuel stored in the bowl constant under all conditions a float system is used. A float operated needle valve and seat at the fuel inlet is used to control the fuel level in the bowl. If the fuel level drops below a certain level the float lowers and opens the valve letting more fuel in. When the float rises it pushes the inlet valve against the seat and shuts off the flow of fuel into the bowl.

Types of carburetors:

There are 3 basic types of carburetors in use today. They are the one barrel, two barrel, and four barrel. Typically, the type of engine and its use will dictate which carburetor is used. In high performance engines multiple carburetors may be used to deliver the amount of fuel required. No matter what type of carburetor your engine uses, National Carburetors is your source for high quality carburetors.

Controlling the speed of the engine:

The throttle controls the speed of the engine by controlling the amount of air fuel allowed in the engine. The throttle is a butterfly valve located after the venturi and is opened by pressing on the gas pedal. The farther the valve is opened the more air/fuel mixture is let into the engine and the faster the engine runs. At low engine speeds when the throttle is only open a little there is not enough air flow to pull in fuel.

Ports

Two ports are used to solve this problem. One port located in the low pressure area and the idle port located below. At low engine speeds both ports draw fuel to keep the engine running. As engine speed increases fuel from the 2 ports decreases until it stops completely.

Handling low speeds:

When the engine is idle there is very little air flowing through the venturi because the throttle valve is closed. The idle port allows the engine to operate under this condition. Fuel is forced through the idle port because of a pressure differential between air in the fuel bowl and vacuum below the throttle valve. Idle fuel mixture is controlled by an adjustable needle valve.

Handling high speeds

Sunday, 27 January 2013

Clutch

Clutch

If you drive a manual transmission car, you may be surprised to find out that it has more than one clutch. And it turns out that folks with automatic transmission cars have clutches, too. In fact, there are clutches in many things you probably see or use every day: Many cordless drills have a clutch, chain saws have a centrifugal clutch and even some yo-yos have a clutch.

In this article, you'll learn why you need a clutch, how the clutch in your car works and find out some interesting, and perhaps surprising, places where clutches can be found.

Clutches are useful in devices that have two rotating shafts. In these devices, one of the shafts is typically driven by a motor or pulley, and the other shaft drives another device. In a drill, for instance, one shaft is driven by a motor and the other drives a drill chuck. The clutch connects the two shafts so that they can either be locked together and spin at the same speed, or be decoupled and spin at different speeds.

In a car, you need a clutch because the engine spins all the time, but the car's wheels do not. In order for a car to stop without killing the engine, the wheels need to be disconnected from the engine somehow. The clutch allows us to smoothly engage a spinning engine to a non-spinning transmission by controlling the slippage between them.

To understand how a clutch works, it helps to know a little bit about friction, which is a measure of how hard it is to slide one object over another. Friction is caused by the peaks and valleys that are part of every surface -- even very smooth surfaces still have microscopic peaks and valleys. The larger these peaks and valleys are, the harder it is to slide the object. You can learn more about friction in How Brakes Work.

A clutch works because of friction between a clutch plate and a flywheel. We'll look at how these parts work together in the next section.

Fly Wheel,Clutch Plates:

In a car's clutch, a flywheel connects to the engine, and a clutch plate connects to the transmission.

When your foot is off the pedal, the springs push the pressure plate against the clutch disc, which in turn presses against the flywheel. This locks the engine to the transmission input shaft, causing them to spin at the same speed.

The amount of force the clutch can hold depends on the friction between the clutch plate and the flywheel, and how much force the spring puts on the pressure plate. The friction force in the clutch works just like the blocks described in the friction section of How Brakes Work, except that the spring presses on the clutch plate instead of weight pressing the block into the ground.

When the clutch pedal is pressed, a cable or hydraulic piston pushes on the release fork, which presses the throw-out bearing against the middle of the diaphragm spring. As the middle of the diaphragm spring is pushed in, a series of pins near the outside of the spring causes the spring to pull the pressure plate away from the clutch disc (see below). This releases the clutch from the spinning engine.

When the clutch pedal is pressed, a cable or hydraulic piston pushes on the release fork, which presses the throw-out bearing against the middle of the diaphragm spring. As the middle of the diaphragm spring is pushed in, a series of pins near the outside of the spring causes the spring to pull the pressure plate away from the clutch disc (see below). This releases the clutch from the spinning engine.

Clutch plate

Note the springs in the clutch plate. These springs help to isolate the transmission from the shock of the clutch engaging.

This design usually works pretty well, but it does have a few drawbacks. We'll look at common clutch problems and other uses for clutches in the following sections.

Common Problems:

From the 1950s to the 1970s, you could count on getting between 50,000 and 70,000 miles from your car's clutch. Clutches can now last for more than 80,000 miles if you use them gently and maintain them well. If not cared for, clutches can start to break down at 35,000 miles. Trucks that are consistently overloaded or that frequently tow heavy loads can also have problems with relatively new clutches.

The most common problem with clutches is that the friction material on the disc wears out. The friction material on a clutch disc is very similar to the friction material on the pads of a disc brake or the shoes of a drum brake -- after a while, it wears away. When most or all of the friction material is gone, the clutch will start to slip, and eventually it won't transmit any power from the engine to the wheels.

The clutch only wears while the clutch disc and the flywheel are spinning at different speeds. When they are locked together, the friction material is held tightly against the flywheel, and they spin in sync. It's only when the clutch disc is slipping against the flywheel that wearing occurs. So, if you are the type of driver who slips the clutch a lot, you'll wear out your clutch a lot faster.

Sometimes the problem is not with slipping, but with sticking. If your clutch won't release properly, it will continue to turn the input shaft. This can cause grinding, or completely prevent your car from going into gear. Some common reasons a clutch may stick are:

Broken or stretched clutch cable - The cable needs the right amount of tension to push and pull effectively.

Leaky or defective slave and/or master clutch cylinders - Leaks keep the cylinders from building the necessary amount of pressure.

Air in the hydraulic line - Air affects the hydraulics by taking up space the fluid needs to build pressure.

Misadjusted linkage - When your foot hits the pedal, the linkage transmits the wrong amount of force.

Mismatched clutch components - Not all aftermarket parts work with your clutch.

A "hard" clutch is also a common problem. All clutches require some amount of force to depress fully. If you have to press hard on the pedal, there may be something wrong. Sticking or binding in the pedal linkage, cable, cross shaft, or pivot ball are common causes. Sometimes a blockage or worn seals in the hydraulic system can also cause a hard clutch.

Another problem associated with clutches is a worn throw-out bearing, sometimes called a clutch release bearing. This bearing applies force to the fingers of the spinning pressure plate to release the clutch. If you hear a rumbling sound when the clutch engages, you might have a problem with the throw-out.

In the next section, we'll examine some different types of clutches and how they are used.

Types of Clutches:

There are many other types of clutches in your car and in your garage.

There are many other types of clutches in your car and in your garage.

An automatic transmission contains several clutches. These clutches engage and disengage various sets of planetary gears. Each clutch is put into motion using pressurized hydraulic fluid. When the pressure drops, springs cause the clutch to release. Evenly spaced ridges, called splines, line the inside and outside of the clutch to lock into the gears and the clutch housing. You can read more about these clutches in How Automatic Transmissions Work.

An air conditioning compressor in a car has an electromagnetic clutch. This allows the compressor to shut off even while the engine is running. When current flows through a magnetic coil in the clutch, the clutch engages. As soon as the current stops, such as when you turn off your air conditioning, the clutch disengages.

Most cars that have an engine-driven cooling fan have a thermostatically controlled viscous clutch -- the temperature of the fluid actually drives the clutch. This clutch is positioned at the hub of the fan, in the airflow coming through the radiator. This type of clutch is a lot like the viscous coupling sometimes found in all-wheel drive cars. The fluid in the clutch gets thicker as it heats up, causing the fan to spin faster to catch up with the engine rotation. When the car is cold, the fluid in the clutch remains cold and the fan spins slowly, allowing the engine to quickly warm up to its proper operating temperature.

Many cars have limited slip differentials or viscous couplings, both of which use clutches to help increase traction. When your car turns, one wheel spins faster than the other, which makes the car hard to handle. The slip differential makes up for that with the help of its clutch. When one wheel spins faster than the others, the clutch engages to slow it down and match the other three. Driving over puddles of water or patches of ice can also spin your wheels. You can learn more about differentials and viscous couplings in How Differentials Work.

Gas-powered chain saws and weed eaters have centrifugal clutches, so that the chains or strings can stop spinning without you having to turn off the engine. These clutches work automatically through the use of centrifugal force. The input is connected to the engine crankshaft. The output can drive a chain, belt or shaft. As the rotations per minute increase, weighted arms swing out and force the clutch to engage. Centrifugal clutches are also often found in lawn mowers, go-karts, mopeds and mini-bikes. Even some yo-yos are manufactured with centrifugal clutches.

Clutches are valuable and necessary to a number of applications.

Here some of the links to know how clutch works

http://www.youtube.com/watch?v=FfjGohWy-OU

http://www.youtube.com/watch?v=c8qsS2g_IiU

Published by Ravindra,Mechanical

Published by Ravindra,Mechanical

If you drive a manual transmission car, you may be surprised to find out that it has more than one clutch. And it turns out that folks with automatic transmission cars have clutches, too. In fact, there are clutches in many things you probably see or use every day: Many cordless drills have a clutch, chain saws have a centrifugal clutch and even some yo-yos have a clutch.

In this article, you'll learn why you need a clutch, how the clutch in your car works and find out some interesting, and perhaps surprising, places where clutches can be found.

|

| Engine without Connecting to Gear Box |

|

| Engine Connecting with GearBox |

In a car, you need a clutch because the engine spins all the time, but the car's wheels do not. In order for a car to stop without killing the engine, the wheels need to be disconnected from the engine somehow. The clutch allows us to smoothly engage a spinning engine to a non-spinning transmission by controlling the slippage between them.

To understand how a clutch works, it helps to know a little bit about friction, which is a measure of how hard it is to slide one object over another. Friction is caused by the peaks and valleys that are part of every surface -- even very smooth surfaces still have microscopic peaks and valleys. The larger these peaks and valleys are, the harder it is to slide the object. You can learn more about friction in How Brakes Work.

A clutch works because of friction between a clutch plate and a flywheel. We'll look at how these parts work together in the next section.

Fly Wheel,Clutch Plates:

In a car's clutch, a flywheel connects to the engine, and a clutch plate connects to the transmission.

When your foot is off the pedal, the springs push the pressure plate against the clutch disc, which in turn presses against the flywheel. This locks the engine to the transmission input shaft, causing them to spin at the same speed.

The amount of force the clutch can hold depends on the friction between the clutch plate and the flywheel, and how much force the spring puts on the pressure plate. The friction force in the clutch works just like the blocks described in the friction section of How Brakes Work, except that the spring presses on the clutch plate instead of weight pressing the block into the ground.

When the clutch pedal is pressed, a cable or hydraulic piston pushes on the release fork, which presses the throw-out bearing against the middle of the diaphragm spring. As the middle of the diaphragm spring is pushed in, a series of pins near the outside of the spring causes the spring to pull the pressure plate away from the clutch disc (see below). This releases the clutch from the spinning engine.

When the clutch pedal is pressed, a cable or hydraulic piston pushes on the release fork, which presses the throw-out bearing against the middle of the diaphragm spring. As the middle of the diaphragm spring is pushed in, a series of pins near the outside of the spring causes the spring to pull the pressure plate away from the clutch disc (see below). This releases the clutch from the spinning engine.Clutch plate

Note the springs in the clutch plate. These springs help to isolate the transmission from the shock of the clutch engaging.

This design usually works pretty well, but it does have a few drawbacks. We'll look at common clutch problems and other uses for clutches in the following sections.

Common Problems:

From the 1950s to the 1970s, you could count on getting between 50,000 and 70,000 miles from your car's clutch. Clutches can now last for more than 80,000 miles if you use them gently and maintain them well. If not cared for, clutches can start to break down at 35,000 miles. Trucks that are consistently overloaded or that frequently tow heavy loads can also have problems with relatively new clutches.

The most common problem with clutches is that the friction material on the disc wears out. The friction material on a clutch disc is very similar to the friction material on the pads of a disc brake or the shoes of a drum brake -- after a while, it wears away. When most or all of the friction material is gone, the clutch will start to slip, and eventually it won't transmit any power from the engine to the wheels.

The clutch only wears while the clutch disc and the flywheel are spinning at different speeds. When they are locked together, the friction material is held tightly against the flywheel, and they spin in sync. It's only when the clutch disc is slipping against the flywheel that wearing occurs. So, if you are the type of driver who slips the clutch a lot, you'll wear out your clutch a lot faster.

Sometimes the problem is not with slipping, but with sticking. If your clutch won't release properly, it will continue to turn the input shaft. This can cause grinding, or completely prevent your car from going into gear. Some common reasons a clutch may stick are:

Broken or stretched clutch cable - The cable needs the right amount of tension to push and pull effectively.

Leaky or defective slave and/or master clutch cylinders - Leaks keep the cylinders from building the necessary amount of pressure.

Air in the hydraulic line - Air affects the hydraulics by taking up space the fluid needs to build pressure.

Misadjusted linkage - When your foot hits the pedal, the linkage transmits the wrong amount of force.

Mismatched clutch components - Not all aftermarket parts work with your clutch.

A "hard" clutch is also a common problem. All clutches require some amount of force to depress fully. If you have to press hard on the pedal, there may be something wrong. Sticking or binding in the pedal linkage, cable, cross shaft, or pivot ball are common causes. Sometimes a blockage or worn seals in the hydraulic system can also cause a hard clutch.

Another problem associated with clutches is a worn throw-out bearing, sometimes called a clutch release bearing. This bearing applies force to the fingers of the spinning pressure plate to release the clutch. If you hear a rumbling sound when the clutch engages, you might have a problem with the throw-out.

In the next section, we'll examine some different types of clutches and how they are used.

Types of Clutches:

There are many other types of clutches in your car and in your garage.

There are many other types of clutches in your car and in your garage.An automatic transmission contains several clutches. These clutches engage and disengage various sets of planetary gears. Each clutch is put into motion using pressurized hydraulic fluid. When the pressure drops, springs cause the clutch to release. Evenly spaced ridges, called splines, line the inside and outside of the clutch to lock into the gears and the clutch housing. You can read more about these clutches in How Automatic Transmissions Work.

An air conditioning compressor in a car has an electromagnetic clutch. This allows the compressor to shut off even while the engine is running. When current flows through a magnetic coil in the clutch, the clutch engages. As soon as the current stops, such as when you turn off your air conditioning, the clutch disengages.

Most cars that have an engine-driven cooling fan have a thermostatically controlled viscous clutch -- the temperature of the fluid actually drives the clutch. This clutch is positioned at the hub of the fan, in the airflow coming through the radiator. This type of clutch is a lot like the viscous coupling sometimes found in all-wheel drive cars. The fluid in the clutch gets thicker as it heats up, causing the fan to spin faster to catch up with the engine rotation. When the car is cold, the fluid in the clutch remains cold and the fan spins slowly, allowing the engine to quickly warm up to its proper operating temperature.

Many cars have limited slip differentials or viscous couplings, both of which use clutches to help increase traction. When your car turns, one wheel spins faster than the other, which makes the car hard to handle. The slip differential makes up for that with the help of its clutch. When one wheel spins faster than the others, the clutch engages to slow it down and match the other three. Driving over puddles of water or patches of ice can also spin your wheels. You can learn more about differentials and viscous couplings in How Differentials Work.

Gas-powered chain saws and weed eaters have centrifugal clutches, so that the chains or strings can stop spinning without you having to turn off the engine. These clutches work automatically through the use of centrifugal force. The input is connected to the engine crankshaft. The output can drive a chain, belt or shaft. As the rotations per minute increase, weighted arms swing out and force the clutch to engage. Centrifugal clutches are also often found in lawn mowers, go-karts, mopeds and mini-bikes. Even some yo-yos are manufactured with centrifugal clutches.

Clutches are valuable and necessary to a number of applications.

Here some of the links to know how clutch works

http://www.youtube.com/watch?v=FfjGohWy-OU

http://www.youtube.com/watch?v=c8qsS2g_IiU

Published by Ravindra,Mechanical

Published by Ravindra,MechanicalSteering Mechanism

Steering Mechanism

You know that when you turn the steering wheel in your car, the wheels turn. Cause and effect, right? But a lot of interesting stuff goes on between the steering wheel and the tires to make this happen.

In this article, we'll see how the two most common types of car steering systems work: rack-and-pinion and recirculating-ball steering. Then we'll examine power steering and find out about some interesting future developments in steering systems, driven mostly by the need to increase the fuel efficiency of cars. But first, let's see what you have to do turn a car. It's not quite as simple as you might think!

You know that when you turn the steering wheel in your car, the wheels turn. Cause and effect, right? But a lot of interesting stuff goes on between the steering wheel and the tires to make this happen.

In this article, we'll see how the two most common types of car steering systems work: rack-and-pinion and recirculating-ball steering. Then we'll examine power steering and find out about some interesting future developments in steering systems, driven mostly by the need to increase the fuel efficiency of cars. But first, let's see what you have to do turn a car. It's not quite as simple as you might think!

Turning the Car:

Turning the Car:You might be surprised to learn that when you turn your car, your front wheels are not pointing in the same direction.

For a car to turn smoothly, each wheel must follow a different circle. Since the inside wheel is following a circle with a smaller radius, it is actually making a tighter turn than the outside wheel. If you draw a line perpendicular to each wheel, the lines will intersect at the center point of the turn. The geometry of the steering linkage makes the inside wheel turn more than the outside wheel.

Rack-Pinion Steering:

Rack-and-pinion steering is quickly becoming the most common type of steering on cars, small trucks and SUVs. It is actually a pretty simple mechanism. A rack-and-pinion gearset is enclosed in a metal tube, with each end of the rack protruding from the tube. A rod, called a tie rod, connects to each end of the rack.

The pinion gear is attached to the steering shaft. When you turn the steering wheel, the gear spins, moving the rack. The tie rod at each end of the rack connects to the steering arm on the spindle (see diagram above).

Rack-and-pinion steering is quickly becoming the most common type of steering on cars, small trucks and SUVs. It is actually a pretty simple mechanism. A rack-and-pinion gearset is enclosed in a metal tube, with each end of the rack protruding from the tube. A rod, called a tie rod, connects to each end of the rack.

The pinion gear is attached to the steering shaft. When you turn the steering wheel, the gear spins, moving the rack. The tie rod at each end of the rack connects to the steering arm on the spindle (see diagram above).

The rack-and-pinion gearset does two things:

It converts the rotational motion of the steering wheel into the linear motion needed to turn the wheels.

It provides a gear reduction, making it easier to turn the wheels.

On most cars, it takes three to four complete revolutions of the steering wheel to make the wheels turn from lock to lock (from far left to far right).

The steering ratio is the ratio of how far you turn the steering wheel to how far the wheels turn. For instance, if one complete revolution (360 degrees) of the steering wheel results in the wheels of the car turning 20 degrees, then the steering ratio is 360 divided by 20, or 18:1. A higher ratio means that you have to turn the steering wheel more to get the wheels to turn a given distance. However, less effort is required because of the higher gear ratio.

Generally, lighter, sportier cars have lower steering ratios than larger cars and trucks. The lower ratio gives the steering a quicker response -- you don't have to turn the steering wheel as much to get the wheels to turn a given distance -- which is a desirable trait in sports cars. These smaller cars are light enough that even with the lower ratio, the effort required to turn the steering wheel is not excessive.

Some cars have variable-ratio steering, which uses a rack-and-pinion gearset that has a different tooth pitch (number of teeth per inch) in the center than it has on the outside. This makes the car respond quickly when starting a turn (the rack is near the center), and also reduces effort near the wheel's turning limits.

|

| Rack Pinon Mechanism |

When the rack-and-pinion is in a power-steering system, the rack has a slightly different design.

Part of the rack contains a cylinder with a piston in the middle. The piston is connected to the rack. There are two fluid ports, one on either side of the piston. Supplying higher-pressure fluid to one side of the piston forces the piston to move, which in turn moves the rack, providing the power assist.

We'll check out the components that provide the high-pressure fluid, as well as decide which side of the rack to supply it to, later in the article. First, let's take a look at another type of steering.

Decirculating Steering Mechanism:

Recirculating-ball steering is used on many trucks and SUVs today. The linkage that turns the wheels is slightly different than on a rack-and-pinion system.

Recirculating-ball steering is used on many trucks and SUVs today. The linkage that turns the wheels is slightly different than on a rack-and-pinion system.The recirculating-ball steering gear contains a worm gear. You can image the gear in two parts. The first part is a block of metal with a threaded hole in it. This block has gear teeth cut into the outside of it, which engage a gear that moves the pitman arm (see diagram above). The steering wheel connects to a threaded rod, similar to a bolt, that sticks into the hole in the block. When the steering wheel turns, it turns the bolt. Instead of twisting further into the block the way a regular bolt would, this bolt is held fixed so that when it spins, it moves the block, which moves the gear that turns the wheels.

Instead of the bolt directly engaging the threads in the block, all of the threads are filled with ball bearings that recirculate through the gear as it turns. The balls actually serve two purposes: First, they reduce friction and wear in the gear; second, they reduce slop in the gear. Slop would be felt when you change the direction of the steering wheel -- without the balls in the steering gear, the teeth would come out of contact with each other for a moment, making the steering wheel feel loose.

Power Steering:

Power steering in a recirculating-ball system works similarly to a rack-and-pinion system. Assist is provided by supplying higher-pressure fluid to one side of the block.

Now let's take a look at the other components that make up a power-steering system.

Power steering in a recirculating-ball system works similarly to a rack-and-pinion system. Assist is provided by supplying higher-pressure fluid to one side of the block.

Now let's take a look at the other components that make up a power-steering system.

There are a couple of key components in power steering in addition to the rack-and-pinion or recirculating-ball mechanism.

*Pump:

The hydraulic power for the steering is provided by a rotary-vane pump (see diagram below). This pump is driven by the car's engine via a belt and pulley. It contains a set of retractable vanes that spin inside an oval chamber.

As the vanes spin, they pull hydraulic fluid from the return line at low pressure and force it into the outlet at high pressure. The amount of flow provided by the pump depends on the car's engine speed. The pump must be designed to provide adequate flow when the engine is idling. As a result, the pump moves much more fluid than necessary when the engine is running at faster speeds.

The pump contains a pressure-relief valve to make sure that the pressure does not get too high, especially at high engine speeds when so much fluid is being pumped.

*Rotary Valve:

A power-steering system should assist the driver only when he is exerting force on the steering wheel (such as when starting a turn). When the driver is not exerting force (such as when driving in a straight line), the system shouldn't provide any assist. The device that senses the force on the steering wheel is called the rotary valve.