Introduction:

carburetor, also spelled carburettor , device for supplying a spark-ignition engine with a mixture of fuel and air. Components of carburetors usually include a storage chamber for liquid fuel, a choke, an idling (or slow-running) jet, a main jet, a venturi-shaped air-flow restriction, and an accelerator pump. The quantity of fuel in the storage chamber is controlled by a valve actuated by a float. The choke, a butterfly valve, reduces the intake of air and allows a fuel-rich charge to be drawn into the cylinders when a cold engine is started. As the engine warms up, the choke is gradually opened either by hand or automatically by heat- and engine-speed-responsive controllers. The fuel flows out of the idling jet into the intake air as a result of reduced pressure near the partially closed throttle valve. The main fuel jet comes into action when the throttle valve is further open. Then the venturi-shaped air-flow restriction creates a reduced pressure for drawing fuel from the main jet into the air stream at a rate related to the air flow so that a nearly constant fuel-air ratio is obtained. The accelerator pump injects fuel into the inlet air when the throttle is opened suddenly.

In the 1970s, new legislation and consumer preferences led automobile manufacturers to improve fuel efficiency and lower pollutant emissions. To accomplish these objectives, engineers developed fuel injection management systems based on new computer technologies. Soon, fuel injection systems replaced carbureted fuel systems in virtually all gasoline engines except for two-cycle and small four-cycle gasoline engines, such as those used in lawn mowers.

If you have read the page entitled How Car Engines Work, you know that the idea behind an engine is to burn gasoline to create pressure, and then to turn the pressure into motion. A remarkably tiny amount of gasoline is needed during each combustion cycle. Something on the order of 10 milligrams of gasoline per combustion stroke is all it takes!

The goal of a carburetor is to mix just the right amount of gasoline with air so that the engine runs properly. If there is not enough fuel mixed with the air, the engine "runs lean" and either will not run or potentially damages the engine. If there is too much fuel mixed with the air, the engine "runs rich" and either will not run (it floods), runs very smoky, runs poorly (bogs down, stalls easily), or at the very least wastes fuel. The carb is in charge of getting the mixture just right.

On new cars, fuel injection is becoming nearly universal because it provides better fuel efficiency and lower emissions. But nearly all older cars, and all small equipment like lawn mowers and chain saws, use carbs because they are simple and inexpensive.

Inside a Carburetor:

The carburetor on a chain saw is a good example because it is so straightforward. The carb on a chain saw is simpler than most carbs because it really has only three situations that it has to cover:

*It has to work when you are trying to start the engine cold.

*It has to work when the engine is idling.

*It has to work when the engine is wide open.

No one operating a chain saw is really interested in any gradations between idle and full throttle, so incremental performance between these two extremes is not very important. In a car the many gradations are important, and this is why a car's carb is a lot more complex.

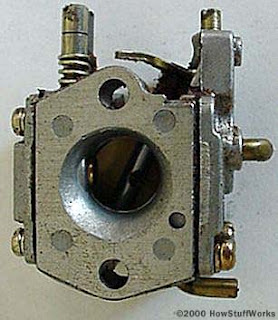

Chainsaw carburetor:

Here are the parts of a carb:

A carburetor is essentially a tube.

There is an adjustable plate across the tube called the throttle plate that controls how much air can flow through the tube. You can see this circular brass plate in photo 2.

At some point in the tube there is a narrowing, called the venturi, and in this narrowing a vacuum is created. The venturi is visible in photo 1

In this narrowing there is a hole, called a jet, that lets the vacuum draw in fuel. You can see the jet on the left side of the venturi in photo 1.

On the step, learn about carburetor tuning and find out why it's so important.

Carburetor Tuning:

The carb is operating "normally" at full throttle. In this case the throttle plate is parallel to the length of the tube, allowing maximum air to flow through the carb. The air flow creates a nice vacuum in the venturi and this vacuum draws in a metered amount of fuel through the jet. You can see a pair of screws on the right top of the carb in photo 2. One of these screws (labeled "Hi" on the case of the chain saw) controls how much fuel flows into the venturi at full throttle.

When the engine is idling, the throttle plate is nearly closed (the position of the throttle plate in the photos is the idle position). There is not really enough air flowing through the venturi to create a vacuum. However, on the back side of the throttle plate there is a lot of vacuum (because the throttle plate is restricting the airflow). If a tiny hole is drilled into the side of the carb's tube just behind the throttle plate, fuel can be drawn into the tube by the throttle vacuum. This tiny hole is called the idle jet. The other screw of the pair seen in photo 2 is labeled "Lo" and it controls the amount of fuel that flows through the idle jet.

Both the Hi and Lo screws are simply needle valves. By turning them you allow more or less fuel to flow past the needle. When you adjust them you are directly controlling how much fuel flows through the idle jet and the main jet.

When the engine is cold and you try to start it with the pull cord, the engine is running at an extremely low RPM. It is also cold, so it needs a very rich mixture to start. This is where the choke plate comes in. When activated, the choke plate completely covers the venturi see this video of the choke plate to see it in action). If the throttle is wide open and the venturi is covered, the engine's vacuum draws a lot of fuel through the main jet and the idle jet (since the end of the carb's tube is completely covered, all of the engine's vacuum goes into pulling fuel through the jets). Usually this very rich mixture will allow the engine to fire once or twice, or to run very slowly. If you then open the choke plate the engine will start running normally.

What does a Carburetor Do?

The carburetor has several functions: 1) it combines gasoline and air creating a highly combustible mixture, 2) it regulates the ratio of air and fuel, and 3) it controls the engine's speed.

How a carburetor mixes fuel and air?

When the piston moves down the cylinder on the intake stroke it draws air from the cylinder and intake manifold. A vacuum is created that draws air from the carburetor. The airflow through the carburetor causes fuel to be drawn from the carburetor through the intake manifold past the intake valves and into the cylinder. The amount of fuel mixed into the air to obtain the required air to fuel ratio is controlled by the venturi or choke. When air flows through the venturi its speed increases and the pressure drops. This causes the fuel to be sucked into the air stream from a hole or jet. When the engine is at idle or at rapid acceleration there is not enough air passing through the venturi to draw fuel. To overcome these problems other systems are used.

Delivering gasoline to the carburetor:

Gasoline is delivered to the carburetor by the fuel pump and is stored in the fuel bowl. To keep this level of fuel stored in the bowl constant under all conditions a float system is used. A float operated needle valve and seat at the fuel inlet is used to control the fuel level in the bowl. If the fuel level drops below a certain level the float lowers and opens the valve letting more fuel in. When the float rises it pushes the inlet valve against the seat and shuts off the flow of fuel into the bowl.

Types of carburetors:

There are 3 basic types of carburetors in use today. They are the one barrel, two barrel, and four barrel. Typically, the type of engine and its use will dictate which carburetor is used. In high performance engines multiple carburetors may be used to deliver the amount of fuel required. No matter what type of carburetor your engine uses, National Carburetors is your source for high quality carburetors.

Controlling the speed of the engine:

The throttle controls the speed of the engine by controlling the amount of air fuel allowed in the engine. The throttle is a butterfly valve located after the venturi and is opened by pressing on the gas pedal. The farther the valve is opened the more air/fuel mixture is let into the engine and the faster the engine runs. At low engine speeds when the throttle is only open a little there is not enough air flow to pull in fuel.

Ports

Two ports are used to solve this problem. One port located in the low pressure area and the idle port located below. At low engine speeds both ports draw fuel to keep the engine running. As engine speed increases fuel from the 2 ports decreases until it stops completely.

Handling low speeds:

When the engine is idle there is very little air flowing through the venturi because the throttle valve is closed. The idle port allows the engine to operate under this condition. Fuel is forced through the idle port because of a pressure differential between air in the fuel bowl and vacuum below the throttle valve. Idle fuel mixture is controlled by an adjustable needle valve.

Handling high speeds

carburetor, also spelled carburettor , device for supplying a spark-ignition engine with a mixture of fuel and air. Components of carburetors usually include a storage chamber for liquid fuel, a choke, an idling (or slow-running) jet, a main jet, a venturi-shaped air-flow restriction, and an accelerator pump. The quantity of fuel in the storage chamber is controlled by a valve actuated by a float. The choke, a butterfly valve, reduces the intake of air and allows a fuel-rich charge to be drawn into the cylinders when a cold engine is started. As the engine warms up, the choke is gradually opened either by hand or automatically by heat- and engine-speed-responsive controllers. The fuel flows out of the idling jet into the intake air as a result of reduced pressure near the partially closed throttle valve. The main fuel jet comes into action when the throttle valve is further open. Then the venturi-shaped air-flow restriction creates a reduced pressure for drawing fuel from the main jet into the air stream at a rate related to the air flow so that a nearly constant fuel-air ratio is obtained. The accelerator pump injects fuel into the inlet air when the throttle is opened suddenly.

In the 1970s, new legislation and consumer preferences led automobile manufacturers to improve fuel efficiency and lower pollutant emissions. To accomplish these objectives, engineers developed fuel injection management systems based on new computer technologies. Soon, fuel injection systems replaced carbureted fuel systems in virtually all gasoline engines except for two-cycle and small four-cycle gasoline engines, such as those used in lawn mowers.

If you have read the page entitled How Car Engines Work, you know that the idea behind an engine is to burn gasoline to create pressure, and then to turn the pressure into motion. A remarkably tiny amount of gasoline is needed during each combustion cycle. Something on the order of 10 milligrams of gasoline per combustion stroke is all it takes!

The goal of a carburetor is to mix just the right amount of gasoline with air so that the engine runs properly. If there is not enough fuel mixed with the air, the engine "runs lean" and either will not run or potentially damages the engine. If there is too much fuel mixed with the air, the engine "runs rich" and either will not run (it floods), runs very smoky, runs poorly (bogs down, stalls easily), or at the very least wastes fuel. The carb is in charge of getting the mixture just right.

On new cars, fuel injection is becoming nearly universal because it provides better fuel efficiency and lower emissions. But nearly all older cars, and all small equipment like lawn mowers and chain saws, use carbs because they are simple and inexpensive.

Inside a Carburetor:

|

| 2.Chainsaw Carburetor |

|

| 1.Chainsaw Carburetor |

*It has to work when you are trying to start the engine cold.

*It has to work when the engine is idling.

*It has to work when the engine is wide open.

No one operating a chain saw is really interested in any gradations between idle and full throttle, so incremental performance between these two extremes is not very important. In a car the many gradations are important, and this is why a car's carb is a lot more complex.

Chainsaw carburetor:

Here are the parts of a carb:

A carburetor is essentially a tube.

There is an adjustable plate across the tube called the throttle plate that controls how much air can flow through the tube. You can see this circular brass plate in photo 2.

At some point in the tube there is a narrowing, called the venturi, and in this narrowing a vacuum is created. The venturi is visible in photo 1

In this narrowing there is a hole, called a jet, that lets the vacuum draw in fuel. You can see the jet on the left side of the venturi in photo 1.

On the step, learn about carburetor tuning and find out why it's so important.

Carburetor Tuning:

The carb is operating "normally" at full throttle. In this case the throttle plate is parallel to the length of the tube, allowing maximum air to flow through the carb. The air flow creates a nice vacuum in the venturi and this vacuum draws in a metered amount of fuel through the jet. You can see a pair of screws on the right top of the carb in photo 2. One of these screws (labeled "Hi" on the case of the chain saw) controls how much fuel flows into the venturi at full throttle.

When the engine is idling, the throttle plate is nearly closed (the position of the throttle plate in the photos is the idle position). There is not really enough air flowing through the venturi to create a vacuum. However, on the back side of the throttle plate there is a lot of vacuum (because the throttle plate is restricting the airflow). If a tiny hole is drilled into the side of the carb's tube just behind the throttle plate, fuel can be drawn into the tube by the throttle vacuum. This tiny hole is called the idle jet. The other screw of the pair seen in photo 2 is labeled "Lo" and it controls the amount of fuel that flows through the idle jet.

Both the Hi and Lo screws are simply needle valves. By turning them you allow more or less fuel to flow past the needle. When you adjust them you are directly controlling how much fuel flows through the idle jet and the main jet.

When the engine is cold and you try to start it with the pull cord, the engine is running at an extremely low RPM. It is also cold, so it needs a very rich mixture to start. This is where the choke plate comes in. When activated, the choke plate completely covers the venturi see this video of the choke plate to see it in action). If the throttle is wide open and the venturi is covered, the engine's vacuum draws a lot of fuel through the main jet and the idle jet (since the end of the carb's tube is completely covered, all of the engine's vacuum goes into pulling fuel through the jets). Usually this very rich mixture will allow the engine to fire once or twice, or to run very slowly. If you then open the choke plate the engine will start running normally.

What does a Carburetor Do?

The carburetor has several functions: 1) it combines gasoline and air creating a highly combustible mixture, 2) it regulates the ratio of air and fuel, and 3) it controls the engine's speed.

How a carburetor mixes fuel and air?

When the piston moves down the cylinder on the intake stroke it draws air from the cylinder and intake manifold. A vacuum is created that draws air from the carburetor. The airflow through the carburetor causes fuel to be drawn from the carburetor through the intake manifold past the intake valves and into the cylinder. The amount of fuel mixed into the air to obtain the required air to fuel ratio is controlled by the venturi or choke. When air flows through the venturi its speed increases and the pressure drops. This causes the fuel to be sucked into the air stream from a hole or jet. When the engine is at idle or at rapid acceleration there is not enough air passing through the venturi to draw fuel. To overcome these problems other systems are used.

Delivering gasoline to the carburetor:

Gasoline is delivered to the carburetor by the fuel pump and is stored in the fuel bowl. To keep this level of fuel stored in the bowl constant under all conditions a float system is used. A float operated needle valve and seat at the fuel inlet is used to control the fuel level in the bowl. If the fuel level drops below a certain level the float lowers and opens the valve letting more fuel in. When the float rises it pushes the inlet valve against the seat and shuts off the flow of fuel into the bowl.

Types of carburetors:

There are 3 basic types of carburetors in use today. They are the one barrel, two barrel, and four barrel. Typically, the type of engine and its use will dictate which carburetor is used. In high performance engines multiple carburetors may be used to deliver the amount of fuel required. No matter what type of carburetor your engine uses, National Carburetors is your source for high quality carburetors.

Controlling the speed of the engine:

The throttle controls the speed of the engine by controlling the amount of air fuel allowed in the engine. The throttle is a butterfly valve located after the venturi and is opened by pressing on the gas pedal. The farther the valve is opened the more air/fuel mixture is let into the engine and the faster the engine runs. At low engine speeds when the throttle is only open a little there is not enough air flow to pull in fuel.

Ports

Two ports are used to solve this problem. One port located in the low pressure area and the idle port located below. At low engine speeds both ports draw fuel to keep the engine running. As engine speed increases fuel from the 2 ports decreases until it stops completely.

Handling low speeds:

When the engine is idle there is very little air flowing through the venturi because the throttle valve is closed. The idle port allows the engine to operate under this condition. Fuel is forced through the idle port because of a pressure differential between air in the fuel bowl and vacuum below the throttle valve. Idle fuel mixture is controlled by an adjustable needle valve.

Handling high speeds

No comments:

Post a Comment

Thank Q Your Feedback is Valuable........